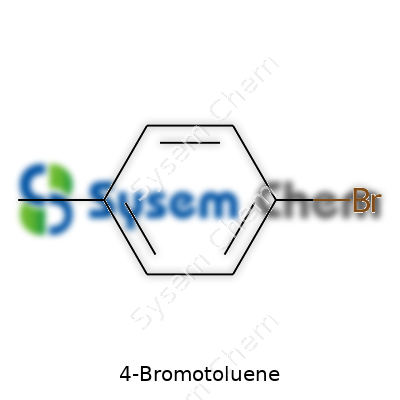

4-Bromotoluene: A Chemical with Deep Roots and Broad Applications

Historical Development

The story of 4-bromotoluene goes back over a century, zigzagging through both industrial progress and curiosity in organic chemistry circles. Chemists in the late 19th and early 20th centuries explored toluene derivatives, not only for their own sake but to understand aromatic substitution and how molecular structure can shape reactivity. There’s no denying that as new dyes, pharmaceuticals, and polymers emerged, 4-bromotoluene proved useful by offering a reliable brominated building block. Industrial synthesis became widespread as manufacturing ramped up for increasingly specialized fields, including intermediates for agrochemicals and photographic chemicals. By tracing publications and patents, one thing becomes clear: the interest grew less from accident and more from the problem-solving attitude common in chemistry labs—making something just a bit more reactive, a bit more selective, a step toward some new and promising molecule.

Product Overview

4-Bromotoluene, known for its clear structure with a bromine atom attached to the para position of a toluene ring, sits in a family of aromatic halides that get used as cross-coupling partners, research tools, and starting points for synthesis. Laboratories and factories choose this compound to make stilbenes, biaryl drugs, and many more chemical assets. Its character comes from both the balance of stability and the ability to undergo further chemical tweaks, opening doors for innovation across multiple sectors. If you walk through a chemical storage facility, the presence of 4-bromotoluene stands out due to both its reliability and the consistent demand from research groups looking to make the leap toward new molecules.

Physical & Chemical Properties

The molecular formula is C7H7Br with a molar mass of about 171 grams per mole. At room temperature, you’ll find it as a colorless to pale yellow liquid, sometimes with a faint odor reminiscent of aromatic solvents found in older chemistry stockrooms. It boils around 184-185 °C, with a melting point resting near -34 °C, which means it pours easily but resists freezing under standard storage. Its density sits comfortably at 1.39 g/cm³, noticeably heavier due to the bromine. The compound dissolves poorly in water but mixes well with common organic solvents; this matters for industrial users relying on separation and purification. Its reactivity gets shaped primarily by the bromine atom’s position, which encourages targeted substitution reactions and enables biaryl coupling processes that wouldn’t work with an unsubstituted toluene.

Technical Specifications & Labeling

Producers label 4-bromotoluene with precise batch numbers, purity levels (usually above 98%), and clear hazard pictograms following international standards, such as GHS. Labels often stress flammability, environmental hazards, and safe handling instructions. For those buying, purity affects yield and selectivity, which impacts downstream reactions. Tight technical specs offer assurance that side-products or contaminants won’t derail a carefully designed synthesis. Each drum or bottle comes stamped with QA/QC documentation, often including trace impurities like dibromotoluene or unreacted toluene, which professional chemists and regulatory officers check before use in sensitive pharmaceuticals or analytical research.

Preparation Method

Commercial synthesis of 4-bromotoluene typically follows an electrophilic aromatic substitution route—treating toluene with bromine in the presence of a Lewis acid, which directs the bromine to the para position. This method rests on years of empirical optimization, balancing temperature, solvent choice, and reaction time to suppress ortho substitution and minimize byproduct formation. In academic circles, milder techniques involving N-bromosuccinimide or alternative brominating reagents occasionally pop up when reaction selectivity or safety matters more. The process might seem straightforward, but practical factors—like managing stoichiometry, handling corrosive reagents, and removing residual starting material—present real-world challenges that industrial chemists address with scale, automation, and waste minimization in mind.

Chemical Reactions & Modifications

Chemists value 4-bromotoluene because the bromine atom opens many doors for cross-coupling reactions such as Suzuki, Heck, and Sonogashira protocols, foundational in modern organic synthesis. These reactions transform the simple aromatic ring into biaryls, styrenes, and more—molecules that act as drugs, materials, or electronic building blocks. Nitration, Friedel–Crafts reactions, or even direct functional group transformations like lithium-halogen exchange let 4-bromotoluene serve as an anchor for more complex molecules, fine-tuning properties for pharmaceutical activity or polymer properties. Every synthetic chemist chasing a new target molecule has likely weighed the pros and cons of bromotoluene derivatives at the planning stage, recognizing that simple tweaks in the starting material can save hours at the bench.

Synonyms & Product Names

Common aliases include p-bromotoluene, 1-bromo-4-methylbenzene, and 4-methylbromobenzene. Suppliers list these names across catalogs to help researchers find the right compound without ambiguity. The CAS number—106-38-7—remains the most reliable identifier across international databases and regulatory filings, ensuring no mix-up during transport or procurement. Recognizing these synonyms helps avoid costly ordering errors and keeps reactions on track, especially in environments managing hundreds of similar-sounding chemicals.

Safety & Operational Standards

While 4-bromotoluene is not the most hazardous compound in a laboratory, it requires respect and appropriate PPE: gloves, goggles, and effective ventilation to minimize exposure. Regulatory agencies categorize it as irritating to the skin and eyes, possibly harmful if inhaled, with environmental precautions owing to aquatic toxicity. GHS symbols on the labeling reinforce these risks. Storage guidelines stress cool, dry, and well-ventilated conditions, away from sources of ignition or strong oxidizers. Efforts to contain, monitor, and neutralize spills or emissions stem from both regulatory compliance and a general commitment to health. I’ve seen how labs running multiple halogenated solvents keep strict logs and spill kits within arm’s reach, a practice that helps prevent small accidents from ballooning into health or safety crises.

Application Area

4-Bromotoluene lands in a variety of fields—pharmaceutical development, agricultural chemicals, electronics, specialty dyes, flavors, and fragrances. Its utility traces to both its moderate reactivity and its role as a customizable starting point. For instance, in drug discovery, medicinal chemists leverage this molecule for rapid analog generation via palladium-catalyzed coupling. In the semiconductor industry, aromatic bromides feed into photoresists and advanced polymers. In fine chemical manufacturing, predictable halogen placement enables efficient synthesis, reducing steps and waste. My own experience in a pharmaceutical lab saw 4-bromotoluene used in parallel synthesis campaigns, offering a good balance between cost, safety, and molecular flexibility compared to other halogenated arenes.

Research & Development

New uses for 4-bromotoluene emerge constantly. Green chemistry projects seek out better catalysts and reduced solvent approaches for both its preparation and its downstream reactions. Academic teams dig into its electronic properties, using it as a model compound to understand substitution effects, radical pathways, or electronic transitions. There’s a push to broaden the scope of coupling partners in biaryl synthesis, looking for more robust and sustainable alternatives. In some projects, researchers optimize automated flow systems to handle larger volumes safely, aiming for cost savings and improved reproducibility. The steady stream of patents in polymer chemistry and drug development underscores its continuing appeal for those seeking reliable building blocks in research pipelines.

Toxicity Research

Data on 4-bromotoluene highlights moderate toxicity. Tests in rodents show that ingestion or inhalation at high doses affects liver and kidney function. Chronic exposure hasn’t shown the severe risks associated with more reactive halogenated solvents, but strong safety data still undergirds all handling protocols. Regulatory authorities list environmentally hazardous effects, especially concerning aquatic life, guiding disposal and spill response procedures both in research and production facilities. Some studies probe its metabolic fate in animals; these experiments steer medical safety thresholds and frame best practices for laboratory and factory settings. Chemical safety culture throughout the industry takes these findings seriously, anchoring risk assessments and incident training for both novice and experienced users.

Future Prospects

The future looks promising for 4-bromotoluene, especially as synthesis moves toward cleaner methods and more efficient catalysts. Automation in chemical manufacturing could make its production safer and more cost-effective, widening access for small-scale users and education programs. In the realm of pharmaceuticals, the drive to diversify drug libraries will keep derivatized arenes like 4-bromotoluene in demand. Green chemistry efforts push for biodegradable alternatives to brominated compounds, which may reduce certain uses, but as synthesis shifts toward sustainability, scalable and less polluting routes may keep 4-bromotoluene relevant in high-value applications. Ongoing studies into its reactivity—especially concerning new catalytic cycles and functional group compatibility—promise to unlock fresh synthetic pathways and more streamlined routes to both established and yet-undiscovered molecules.

Understanding 4-Bromotoluene’s Chemical Formula

4-Bromotoluene has the chemical formula C7H7Br. It’s a benzene ring with a methyl group attached at one site and a bromine atom at the position opposite the methyl group. That “4-” in its name points straight to the bromine sitting on the fourth carbon if you start counting at the methyl group. Structurally, the molecule keeps things clear: aromatic ring, one methyl, one bromine. I remember student lab benches covered in aromatic compounds like this, the air full of anecdotes about safe practice handling anything with a halogen.

Why Chemical Structure Matters in Real Life

Anyone who’s spent time in a lab has seen first-hand how one change on a molecule makes a world of difference. Swapping a hydrogen for a bromine shifts physical properties right away. 4-Bromotoluene, thanks to that heavy bromine atom, has a higher boiling point than plain toluene. That methyl group helps keep the compound less volatile and more manageable than unsubstituted bromobenzene. It dissolves well in organic solvents but not water, a factor that always affects solubility, separation, and cleanup. Safety goggles stay on whenever handling this one, since aromatic bromides have a well-earned reputation for being irritating or toxic.

Why 4-Bromotoluene Turns Up in Chemistry Settings

I’ve seen many research projects where 4-Bromotoluene acts as a key stepping stone. Chemists use it to build something bigger: pharmaceuticals, dyes, pesticides, and specialty polymers. One memorable project at my university used this compound as the base for Suzuki coupling reactions. It reacts strongly at the bromine site, allowing other groups to be attached precisely where chemists want them, which means they can design advanced molecules with careful control. That targeting depends on the para placement of the bromo and methyl groups, steering where further reactions hit the ring.

Potential Challenges When Working with 4-Bromotoluene

Working with halogenated aromatics means taking care every step of the way. Spills stink up the workspace and can cause headaches and skin irritation. Labs address these dangers with fume hoods and proper glove use. Waste handling creates another headache, since brominated organic compounds demand special disposal and environmental control. The byproducts and effluent need careful treatment so bromine atoms don’t end up released into the environment, where they could cause problems for water, soil, or local wildlife.

Better Handling: Solutions from Daily Practice

Over the years, I’ve found that simple routines make the biggest difference. Regularly checking vents and airflow in the lab cuts down risk. Training students to handle reagents gently and manage spills right away makes the lab safer for everyone. For chemical waste, one approach separates out solvents containing brominated aromatics from others, sending them for incineration instead of regular disposal. Building these habits into the culture of a lab keeps accidents rare and protects everyone’s health.

Importance Beyond the Laboratory

Chemicals like 4-Bromotoluene highlight the links between bench science and the greater world. Every synthetic advance, each new drug or advanced material makes life easier—but it all starts with careful chemistry, well-chosen molecules, and smart lab practices. Remembering the role of each compound, from its formula to its safety needs, keeps both experiments and their results on solid ground.

Everyday Chemistry in Action

Think back to high school chemistry class. I remember the distinct smell of reagents, the nervous energy as classmates handled beakers, the curiosity behind every new reaction. Some chemicals, you learn quickly, live on as background players in much bigger stories. 4-Bromotoluene joins this league, running quietly behind scenes in pharmaceutical labs, dye houses, and classrooms. It does not make headlines, yet whole branches of science rely on it.

Engine of Organic Synthesis

There is a reason so many synthesis reactions start with 4-Bromotoluene. With its reactive bromine atom stuck to a methyl-substituted benzene ring, it offers up a launchpad for chemists. In college, I watched it convert quickly in Suzuki and Heck couplings, which help build brand-new carbon-carbon bonds. Those bonds can grow into much larger molecules — some become new medicine, others grow into advanced polymers. Organic chemists count on this compound every week, sometimes every day, because it shaves steps from complex syntheses.

Spinning Out Pharmaceuticals

Drugs don’t jump fully formed out of nowhere. They develop through careful, intricate reactions. In pharmaceutical R&D, 4-Bromotoluene enables the efficient construction of complex aromatic compounds. It's a reliable building block in painkillers, antibiotics, and antipsychotic drugs. I’ve seen research notes from colleagues in pharma documenting how the stability of this compound means fewer headaches from unwanted side reactions. Consistency matters in medicine — lives hang in the balance.

Driving New Dyes and Pigments

Color doesn’t just happen; those bright reds and deep blues in textiles and inks reach us after a series of chemical steps. Dye manufacturers use 4-Bromotoluene to introduce brominated aromatic rings, laying down the foundation for more vivid, longer-lasting colors. Some of the boldest, most colorfast garments start with this single ingredient. In polymer chemistry courses, I watched it become a launching point for entire classes of colorants. These are the hues found in printers, paints, and art supplies worldwide.

Emerging Materials and Specialty Chemicals

Not all uses get as much press as pharmaceuticals or dyes. Polymer scientists also grab 4-Bromotoluene to add substituents that tweak flexibility, heat resistance, or electrical conductivity. Some advanced materials — think flexible electronics, robust adhesives — come to life because 4-Bromotoluene helped lay the groundwork. Research articles and patents frequently list it among the “starting materials” for molecular innovations. Its unique position on the benzene ring opens doors to new possibilities.

Safety and Supply Chain Concerns

With all these applications, handling and sourcing 4-Bromotoluene requires responsibility. It can irritate skin and eyes, and inhalation hazards remind us that lab safety isn’t optional. Chemical suppliers do rigorous quality checks now, keeping impurities low so downstream reactions run as planned. I’ve seen labs pivot suppliers to prevent production delays — not all shipments arrive pure or on time. The push for greener chemistry brings in talk of recycling or alternative synthesis strategies, aiming to maintain quality while trimming the environmental footprint.

Looking Ahead

4-Bromotoluene isn’t going anywhere. Its value in research and industry comes from a mix of reliability, versatility, and raw efficiency. As demand grows in life sciences and advanced manufacturing, new ways to produce and deploy it will keep emerging. Adapting these methods and promoting safe, sustainable practices will shape the future for everyone — chemists, workers, end users.

Why Extra Care Matters

Working with chemicals like 4-Bromotoluene takes more than reading a safety label. Even if this compound doesn’t get flagged as the most aggressive toxin, it still packs risks that can sneak up on you in any lab or production setting. Too many folks learn the hard way—skin reactions, unexpected vapors, or spills that set off alarms and cause headaches for everyone involved. My own early days in the lab taught me that rushing with these compounds never pays off. One careless move led to a rushed eyewash station visit and a stern talking-to from my supervisor. Some lessons stick.

Personal Protective Equipment: Gear Makes the Difference

Sometimes, people start to cut corners with gloves and eye protection after handling the same chemicals over and over. Still, 4-Bromotoluene isn’t something to mess with barehanded. Disposable nitrile gloves work best—not latex—since nitrile resists permeation better. Splash goggles do more than look official; they block unexpected droplets that sting or even cause eye damage. Lab coats and long pants help shield arms and legs, and closed shoes beat open-toes any day, especially if a spill rolls off the bench.

Managing Vapors and Spills

4-Bromotoluene gives off vapors that can irritate the nose and throat. Anyone weighing or transferring the stuff needs good ventilation. Fume hoods aren’t just for show—they pull those fumes away, keeping the air cleaner and making sure you won’t get hit hard after only a few minutes of exposure. For spills, most labs keep spill kits right within reach. Make sure everything gets wiped up using absorbents made for organics, and the waste goes straight to the right chemical disposal bins. You don’t want to risk a fire or chemical reaction in the trash.

Storage Rules: Out of Sight Doesn’t Mean Out of Mind

Keeping 4-Bromotoluene sealed and labeled stops evaporative loss and clears up confusion about what’s in each bottle. Don’t stash this chemical near oxidizers. I’ve seen friends learn that hard way after a leaky cap led to more than one storage room evacuation. Storing it in a cool, dry place with secondary containment trays keeps bottles upright and accidental breakage at bay. Routine inventory checks help avoid mystery bottles sitting half-forgotten in the back.

Training and Emergency Preparedness

No matter how much lab experience you have, refresher safety training gives everyone the chance to keep good habits sharp. Make sure everyone knows the emergency phone numbers, where to find eyewash stations, and how to use the safety shower. Simple drills make a real difference in response time. Most important: no one should ever work with 4-Bromotoluene alone. A buddy nearby helps in case something goes sideways.

Respect for the Compound Leads to Fewer Accidents

The science behind 4-Bromotoluene won’t change, but the human side—attitude, attention, and how carefully people follow safety steps—makes all the difference in avoiding trouble. Safe lab work relies on upfront communication, real protective equipment, and storage rules based on experience, not convenience. Anyone who puts safety first leaves the lab with their health and reputation—for themselves and their team—fully intact.

Getting to Know 4-Bromotoluene

Working in a chemistry lab, it's almost impossible not to encounter 4-bromotoluene at some point. This compound, with the simple formula C7H7Br, brings together a toluene ring and a bromine atom sitting on the para position. On paper, it might not seem like a breakthrough chemical, but its role in organic synthesis and material development makes it pretty common on the lab shelf.

Boiling Point: The Practical Figure

The reported boiling point for 4-bromotoluene clocks in around 199°C. If you’ve spent time working with organic compounds, numbers like this carry real meaning. A boiling point below 200°C means this liquid can turn into vapor with just some moderate heating on a hot plate. Compare this with its cousin, toluene, which boils at about 111°C. Tossing a bromine atom onto the ring packs in more mass and changes electron distribution, raising the boiling temperature by nearly 90 degrees.

This difference in boiling points matters far beyond trivia night. Purification steps, like distillation, depend on small differences. A clear-cut temperature lets chemists isolate products, avoid degradation, and separate compounds efficiently. If the boiling point hovered too close to other aromatic solvents, isolating pure 4-bromotoluene would eat up more time and resources.

Lab Safety and Handling

Nobody wants to breathe in chemical vapors longer than necessary. That near-200°C mark means 4-bromotoluene gives off fewer fumes at room temperature. For the chemists in the room, this property helps reduce low-level chronic exposure—something you really start to appreciate after a few long days by the bench. Still, once it gets heated up for a reaction or a clean-up, take care. Efficient fume hoods and personal protective gear never go out of style. Studies have shown that brominated compounds can cause breathing problems and skin irritation, so it pays to respect the compound, no matter how familiar it gets.

The Boiling Point in Research and Industry

Industrial production of 4-bromotoluene requires effective temperature management. During scale-up, overheating can break down product or build up pressure in reactors. Over the last decade, attention to safer process design has reduced the risks. Automated reactors and better monitoring allow for tight control over heating, keeping operations safer.

Boiling point plays a role in environmental risk, too. Compounds that vaporize quickly enter the atmosphere and can travel far from a production site. The higher boiling point for 4-bromotoluene limits rapid evaporation. This cuts down on air contamination but shifts the risk toward spills or improper disposal, which can affect soil and water instead. Environmental scientists look at data like this before setting handling guidelines or investigating pollution events.

Safer Alternatives and Solutions

Some companies look for alternatives when possible, preferring chemicals that break down faster in the environment or that boast lower toxicity. Green chemistry initiatives encourage substitution and safer synthesis techniques. Still, as long as the structure of 4-bromotoluene serves a unique purpose—especially in pharmaceutical and materials research—it will show up on order forms.

Clear technical data, practical lab experience, and regular safety reviews all help support good decisions in handling and working with 4-bromotoluene. For the day-to-day chemist, knowing the boiling point isn’t just a fact—it’s an everyday tool shaping how research and production move forward.

Understanding 4-Bromotoluene’s Risks

Anyone who has spent time in a chemistry lab knows there’s nothing glamorous about storing organic chemicals. 4-Bromotoluene looks pretty tame on its safety label, but I remember the strong odor from a sample in grad school that lingered for hours. Subtle reminders like these reinforce why storage habits shape safety outcomes. This chemical – used in dyes, pharmaceuticals, and other industrial syntheses – doesn’t grab headlines. Yet poor handling and careless storage have led to a few memorable emergency drills over the years, both in university and in industry.

Temperature and Ventilation: Consistency Rules

Most fire codes and chemical supply data agree on a baseline: store 4-Bromotoluene in a cool, dry place. I’ve seen “room temperature” defined in many ways by lab managers, but the point isn’t to nitpick degrees Celsius; just avoid heat sources and keep the substance away from direct sunlight. I’ve witnessed a bottle sweating under a lightbulb’s heat grow brittle in just months. Certain organic compounds, exposed to repeated temperature swings, break down faster, emit vapors, or worse, cause pressure build-up in sealed containers. That’s not a scenario anyone wants to manage late at night.

Containment Counts

Poor seals create major headaches. In a shared lab, a cracked cap means fumes, and those spread fast. Glass offers solid chemical resistance, but only if intact. Never force a stopper if the threads bind or flake – worn-out caps become leak risks. Use containers with tight-fitting lids and avoid switching bottles unless the new one is specifically labeled and rated for organics. A friend once moved 4-Bromotoluene to a plastic squeeze bottle. The next day, it softened and crumpled, spreading the contents onto a benchtop. Stick to amber or clear glass if you can, because plastic varieties usually degrade with time and exposure.

Labeling and Segregation: Avoiding Mix-Ups

Even in companies with digital logs and barcodes, physical labeling still wins the day. More than once I’ve seen someone reach for a clear liquid, only to realize later a faded label hid its identity. Always mark the content and date on the bottle, and update this if you split or decant anything. Place halogenated organics like 4-Bromotoluene away from acids, oxidizers, and strong bases. Just one slip in shelving protocol led to a “who mixed the shelf” panic at a startup I once worked at. Cross-contaminating chemicals isn’t just a storage error— it risks real reactions, some of which can start fires or worse.

Practicing What’s Preached

Everyone benefits when safety checks are routine, not reactionary. A walk-through every month to look for leaks, failures on caps, or misplaced bottles saves more than just regulatory hassle. During a recent site audit, a quick glance caught two aging containers with barely legible dates tucked in a back corner. Quick action kept that from turning into a disposal headache or a reportable incident. Records, vigilance, and a bit of everyday skepticism do more to prevent accidents than fancy storage cabinets alone.

Safeguarding People, Not Just Chemicals

Storing 4-Bromotoluene isn’t about perfection— it’s about showing respect for the people who share the space. A clean, labeled shelf, a cool room with solid air flow, and regular checks on containers all point to a culture that values health and safety. Those are habits worth keeping, and the low drama only goes to show the work’s being done right.